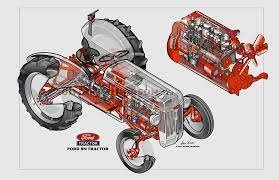

In the vast and varied world of agricultural machinery, the tractor stands as a cornerstone of modern farming, offering the power and versatility needed to meet a wide array of agricultural tasks head-on.

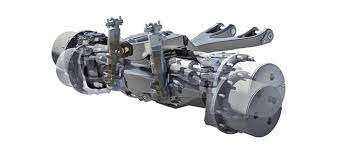

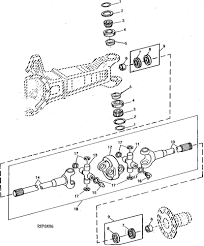

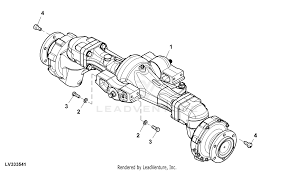

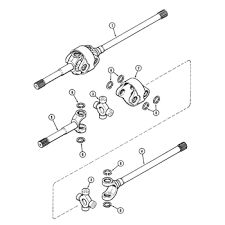

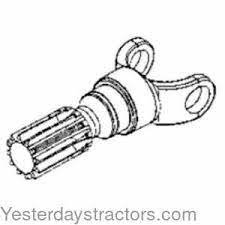

At the heart of this workhorse’s functionality is its front axle shaft assembly—a key component ensuring that power is transmitted efficiently from the engine to the wheels, enabling tractors to navigate and operate across different terrains.

This comprehensive guide is designed to provide global tractor parts buyers with an in-depth understanding of front axle shaft assemblies, covering everything from design considerations and material selection to manufacturing processes, maintenance strategies, and global standards compliance.

Chapter 1: Design Innovations in Front Axle Shaft Assemblies

1.1 Understanding the Basics

At its core, the design of a front axle shaft assembly is geared towards durability, efficiency, and adaptability. It must withstand the high torque and stresses of agricultural operations while ensuring stability and agility for various tasks.

1.2 Advanced Design Features

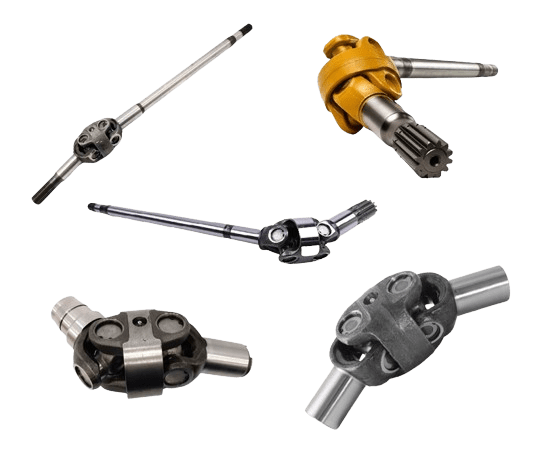

- Modular Designs: Emerging trends in axle design focus on modular constructions, allowing for easier customization and repair, accommodating the diverse needs of agricultural machinery.

- Integrated Technology: Incorporation of smart sensors and IoT technology for real-time monitoring of wear and performance, enhancing predictive maintenance capabilities.

Chapter 2: Material Selection and Durability

2.1 Steel Alloys: The Backbone of Durability

- Carbon Steels: Offers an optimal balance of strength and affordability, making it a popular choice among manufacturers.

- Advanced High-Strength Steels (AHSS): Provides enhanced durability and resistance to wear, essential for high-stress applications.

2.2 The Rise of Composite Materials

- Carbon Fiber Reinforced Polymers: While more expensive, they offer significant weight reductions and improved fuel efficiency, a trade-off that’s increasingly justified with advances in manufacturing techniques.

Chapter 3: Manufacturing Processes and Innovations

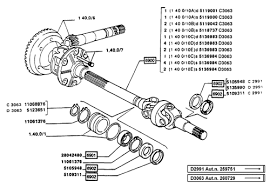

3.1 From Forging to Finishing

- Forging: A detailed look at how forging shapes the raw steel into the initial form of the axle, setting the stage for durability.

- Machining: Precision machining processes are crucial for achieving the exact dimensions and surface finishes required for optimal performance.

3.2 Heat Treatment Techniques

- Quenching and Tempering: Explores how these processes enhance the mechanical properties of steel alloys, increasing the resilience of the axle shafts against the rigors of agricultural use.

Chapter 4: Maintenance and Repair: Ensuring Longevity

4.1 Regular Inspection and Maintenance

- Detailed guidelines on conducting thorough inspections, identifying early signs of wear, and implementing regular maintenance routines to extend the life of axle assemblies.

4.2 Advanced Maintenance Techniques

- Predictive Maintenance: Utilizing data from integrated sensors to anticipate and address potential failures before they occur, significantly reducing downtime.

Chapter 5: Navigating Global Standards and Compliance

5.1 ISO 9001 and Quality Management

- An in-depth discussion on how adhering to ISO 9001 standards ensures consistent quality in manufacturing processes and customer service.

5.2 IATF 16949: Automotive Quality Excellence

- Examination of how the IATF 16949 standard, while more specific to the automotive sector, is pivotal in driving quality and reliability in tractor front axle manufacturing.

5.3 ISO 14001: Environmental Management

- The importance of environmental management in the production of tractor parts, and how ISO 14001 certification helps manufacturers minimize their environmental footprint while ensuring regulatory compliance.

Chapter 6: The Future of Tractor Front Axle Assemblies

6.1 Technological Advancements and Material Innovations

- Smart Materials: Exploration of materials that can adapt their properties in real-time to changing environmental conditions, offering the potential for self-healing axle assemblies.

6.2 Sustainability and Manufacturing

- Strategies for making the production of front axle shaft assemblies more sustainable, including the use of recycled materials and energy-efficient manufacturing processes.

Conclusion

The world of tractor front axle shaft assemblies is one of complex engineering, sophisticated design, and stringent standards, all aimed at ensuring the efficiency, reliability, and longevity of one of agriculture’s most vital pieces of machinery.

For global tractor parts buyers, understanding these intricacies is key to making informed decisions that not only meet their immediate needs but also align with broader trends towards sustainability, technological integration, and enhanced performance.

Through continual innovation and adherence to global quality standards, the industry is poised to meet the challenges of modern agriculture, driving productivity and sustainability forward.