In the world of agricultural machinery, the tractor stands as the workhorse, pivotal to the operations that sustain farms across the globe.

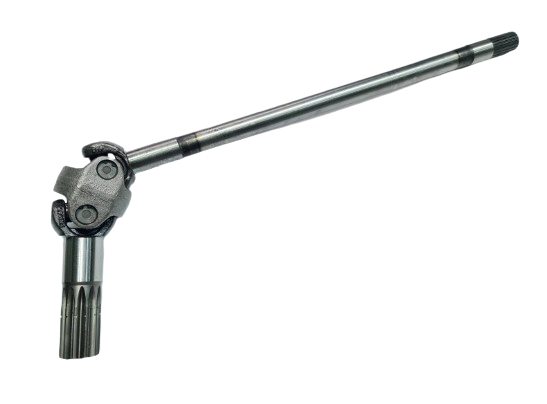

At the heart of these mechanical beasts are components engineered for resilience and efficiency, among which the front axle shaft plays a critical role.

As the linchpin that transmits power from the engine to the wheels, ensuring the durability and performance of these shafts is paramount.

This is where the advancements in materials science, specifically the development and utilization of high-strength alloys, come into play.

The Critical Role of Front Axle Shafts in Tractors

The front axle shaft of a tractor is more than just a component; it’s a crucial element that bears the brunt of various stresses and strains during agricultural operations.

Whether plowing, tilling, or hauling, the front axle shaft must withstand the torsional and bending forces exerted upon it.

Any failure in this component can lead to downtime, increased maintenance costs, and significant losses in productivity.

High-Strength Alloys: A Game Changer for Durability and Performance

The pursuit of materials that can endure the rigorous demands of tractor operations has led engineers and scientists to develop high-strength alloys.

These materials, crafted through the manipulation of chemical compositions and manufacturing processes, offer superior properties compared to traditional steel or iron used in older tractor models.

1. Steel Alloys: The Backbone of Modern Tractor Shafts

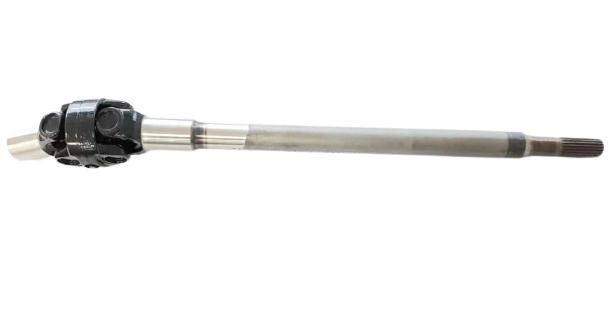

The most commonly utilized materials in the production of tractor front axle shafts are steel alloys.

These alloys, particularly those enhanced with carbon, chromium, and molybdenum, provide an optimal balance of strength, toughness, and wear resistance.

High-strength low-alloy (HSLA) steels, for instance, are favored for their exceptional strength-to-weight ratio, allowing for the design of lighter, more fuel-efficient tractors without compromising durability.

2. Advancements in Material Science: Beyond Traditional Alloys

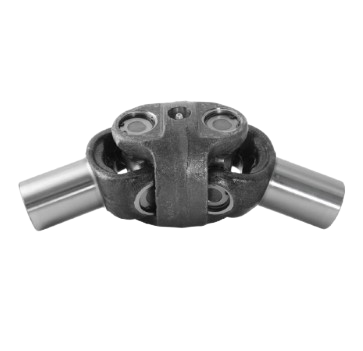

Innovation in material science has not stopped with steel. Newer formulations and composites are being explored to push the boundaries of what is possible.

Materials such as advanced high-strength steels (AHSS) and metal matrix composites (MMC) offer heightened levels of durability and stress tolerance.

These materials undergo sophisticated treatment processes, including quenching and tempering, to enhance their mechanical properties, making them ideal for critical components like tractor front axle shafts.

The Benefits of High-Strength Alloys in Tractor Shaft Production

Enhanced Durability

The primary advantage of high-strength alloys is their remarkable durability.

These materials can withstand the cyclic loading and unloading, torsional stresses, and bending moments that are typical in agricultural operations.

The result is a front axle shaft that maintains its integrity and performance over extended periods, reducing the need for frequent replacements.

Improved Performance

High-strength alloys enable the design of axle shafts that are not only more robust but also more efficient.

With improved material strength, shafts can be designed to be lighter without sacrificing performance. This weight reduction translates to better fuel efficiency and easier handling of the tractor, contributing to more sustainable and cost-effective farming practices.

Resistance to Wear and Corrosion

Another significant benefit is the alloys’ resistance to wear and corrosion.

This resistance is crucial in the harsh environments tractors operate in, where dirt, moisture, and chemicals are prevalent.

High-strength alloys, especially those with added chromium, offer an extra layer of protection against these elements, prolonging the life of the axle shafts.

Challenges and Considerations

While the advantages are clear, the adoption of high-strength alloys in tractor front axle shaft production is not without its challenges.

The cost of these materials and the complexity of their manufacturing processes can be higher than traditional materials. However, when balanced against the extended lifespan and reduced maintenance costs, high-strength alloys represent a sound investment for the future of agricultural machinery.

The Future of Tractor Front Axle Shafts

The future of tractor front axle shafts lies in the ongoing innovation within materials science.

As researchers continue to develop and refine high-strength alloys, we can expect to see even more durable, efficient, and environmentally friendly components.

These advancements will not only benefit the agricultural industry by enhancing the reliability and performance of machinery but also contribute to the broader goals of sustainability and resource conservation.

Conclusion

The evolution of materials used in the production of tractor front axle shafts is a testament to the incredible strides made in materials science and engineering.

High-strength alloys have emerged as the material of choice for these critical components, offering unparalleled durability, performance, and resistance to wear and corrosion.

As we continue to explore and innovate, the future of agricultural machinery looks promising, with stronger, more efficient, and more reliable tractors leading the way in feeding the world.