In the world of agricultural machinery, the durability and performance of a tractor are paramount.

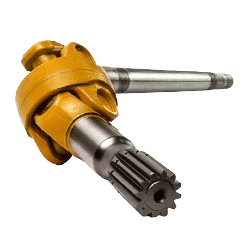

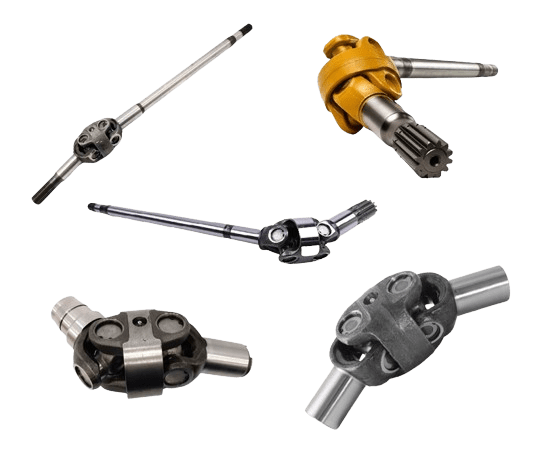

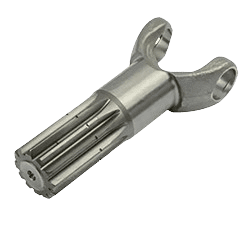

Central to this performance are the tractor half-shafts, which play a crucial role in transmitting power from the engine to the wheels.

The strength and toughness of these half-shafts directly impact the tractor’s efficiency, reliability, and longevity.

With the advancement of material science and manufacturing technology, innovative heat treatment methods have emerged as key to enhancing these properties, offering a new paradigm in agricultural machinery durability and performance.

The Importance of Heat Treatment

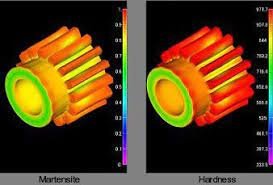

Heat treatment is a controlled process of heating and cooling metals to alter their microstructural properties.

This process is essential for improving various characteristics such as strength, hardness, toughness, and wear resistance.

Traditional heat treatment methods have served the industry well, but as the demands on agricultural machinery grow, the need for more advanced and effective treatments becomes apparent.

Advancements in Heat Treatment Technologies

The quest for superior mechanical properties has led to the development of several innovative heat treatment techniques.

These methods aim to provide enhanced strength and toughness, meeting the evolving needs of the agricultural sector.

Laser Heat Treatment

Laser heat treatment stands out for its precision and efficiency.

This method allows for targeted heating of specific areas of the half-shaft, minimizing distortion and enhancing the material’s mechanical properties in critical areas.

The ability to focus on particular sections of the component without affecting the overall integrity of the metal is a significant advancement over traditional uniform heat treatments.

Induction Hardening

Induction hardening offers another leap forward, using electromagnetic induction to heat the metal quickly and selectively.

This process achieves a hardened surface layer while maintaining the core’s toughness, making tractor half-shafts more resistant to wear and fatigue.

The speed and control of induction hardening make it an attractive option for large-scale production, ensuring consistent results and high-quality components.

Cryogenic Treatment

Expanding the boundaries of conventional heat treatment, cryogenic treatment involves cooling the metal to extremely low temperatures, often near -190°C (-310°F).

This process refines the microstructure of the steel, eliminating residual stresses and enhancing both toughness and wear resistance.

When combined with traditional heat treatment methods, cryogenic treatment can significantly extend the life of tractor half-shafts.

The Benefits for Agricultural Machinery

The integration of these innovative heat treatment methods into the manufacturing of tractor half-shafts brings substantial benefits.

By significantly improving the strength and toughness of these components, tractors become more reliable and durable, capable of withstanding the rigorous demands of modern agriculture.

This translates to reduced maintenance costs, longer service intervals, and increased productivity for farmers and agricultural businesses.

Moreover, the enhanced performance of tractor half-shafts contributes to overall tractor efficiency.

With components that are better suited to handle high loads and stress, tractors can operate more effectively, providing optimal power transmission and fuel efficiency.

This not only helps farmers achieve better yields but also supports sustainability through reduced energy consumption and lower emissions.

AG Tractor Parts Co., Ltd.: Leading the Way

At AG Tractor Parts Co., Ltd., we are committed to leveraging these innovative heat treatment methods to produce tractor half-shafts that set the industry standard for strength, toughness, and reliability.

Our dedication to quality and innovation ensures that our customers receive components that not only meet but exceed their expectations.

We understand the critical role that tractor half-shafts play in agricultural operations, and we strive to provide solutions that enhance the performance and longevity of your machinery.

By choosing AG Tractor Parts Co., Ltd., you are investing in the future of agriculture, where durability, efficiency, and performance drive success.

Conclusion

The evolution of heat treatment methods marks a significant milestone in the development of agricultural machinery. I

nnovative techniques such as laser heat treatment, induction hardening, and cryogenic treatment are revolutionizing the way tractor half-shafts are manufactured, offering unprecedented levels of strength and toughness. As AG Tractor Parts Co., Ltd.

embraces these advancements, we invite our customers to experience the benefits of our cutting-edge components.

Together, we can achieve new heights in agricultural productivity and efficiency, powered by innovation and driven by quality.