In the realm of agricultural machinery, the tractor stands as the indomitable workhorse, critical to operations large and small across the globe.

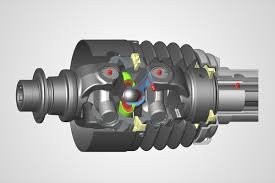

Central to its functionality is the tractor front universal joint shaft, a component that epitomizes the fusion of robust engineering and precision manufacturing.

As the agricultural sector evolves, so too does the demand for more innovative and sustainable practices in the creation of these essential parts.

This exploration delves deep into the advancements shaping tractor front universal joint shaft manufacturing and the sustainable practices that are setting new benchmarks for the future of agricultural machinery.

1. The Role of Innovation in Tractor Front Universal Joint Shaft Manufacturing

The agricultural industry’s push towards higher efficiency and reliability in machinery has placed the spotlight on the manufacturing of tractor front universal joint shafts.

Innovations in this space are multifaceted, focusing on materials, engineering processes, and the integration of smart technologies.

- High-Strength Materials: The shift towards materials such as advanced alloys and high-performance composites has been a game-changer. These materials offer an unmatched combination of strength and lightness, reducing the overall weight of the tractor while enhancing the durability and lifespan of the shafts.

- Precision Engineering: Utilizing cutting-edge CAD and CAM technologies has allowed for a level of precision previously unattainable. These tools enable the design and production of complex shapes and configurations, optimizing the performance of the shafts under various conditions.

- Digitalization and Smart Manufacturing: The adoption of IoT and AI in manufacturing processes has ushered in a new era of efficiency and quality control. Real-time monitoring and predictive analytics help in preempting failures and ensuring that every shaft meets exacting standards.

2. Sustainability in Manufacturing Processes

Sustainability is no longer just a buzzword but a guiding principle in tractor front universal joint shaft manufacturing. The industry is embracing practices that not only benefit the environment but also enhance operational efficiency and cost-effectiveness.

- Eco-Friendly Materials: The exploration and adoption of sustainable materials, including recycled metals and bio-based composites, are reducing the environmental footprint of manufacturing processes. These materials not only diminish the reliance on non-renewable resources but also pave the way for the next generation of eco-conscious agricultural machinery.

- Energy Efficiency: Innovations in manufacturing technology are increasingly focusing on reducing energy consumption. From the deployment of renewable energy sources to the introduction of more efficient machinery, the industry is making strides towards a greener production process.

- Waste Reduction and Recycling: Embracing the principles of the circular economy, manufacturers are implementing strategies to minimize waste and maximize resource utilization. This includes the recycling of scrap materials, the refurbishment of parts, and the design of products with end-of-life disassembly in mind.

3. Case Studies: Leading the Charge in Innovation and Sustainability

Several industry leaders are exemplifying the potential of integrating innovation and sustainability into manufacturing practices.

- Case Study 1: A company that has revolutionized the use of high-strength, lightweight materials, significantly reducing the carbon footprint of their manufacturing process while enhancing the performance of their tractor shafts.

- Case Study 2: An enterprise that has fully embraced digitalization, implementing a smart factory framework that allows for unprecedented levels of precision and efficiency in the production of universal joint shafts.

- Case Study 3: A manufacturer that has set new standards in sustainability, utilizing 100% recycled materials in their production process and pioneering energy-saving manufacturing techniques.

4. Challenges and Opportunities

While the path towards innovation and sustainability in tractor front universal joint shaft manufacturing is promising, it is not without its challenges.

The initial costs of adopting new technologies and processes can be significant, and there is often a learning curve associated with their implementation.

However, the opportunities these advancements present are considerable, offering the potential for reduced operational costs, enhanced product quality, and access to new markets increasingly demanding sustainable practices.

5. The Future of Tractor Front Universal Joint Shaft Manufacturing

Looking ahead, the future of tractor front universal joint shaft manufacturing is bright, with continued innovations and a deeper commitment to sustainability on the horizon.

Advances in materials science, further integration of digital technologies, and a growing emphasis on circular economy principles are set to redefine what is possible in agricultural machinery manufacturing.

Conclusion

The journey towards innovation and sustainability in tractor front universal joint shaft manufacturing is both challenging and rewarding.

As the industry continues to evolve, the commitment to advancing these practices is clear.

By embracing new technologies and sustainable practices, manufacturers are not only enhancing the performance and efficiency of agricultural machinery but are also contributing to a more sustainable