Introduction: Revolutionizing Agricultural Machinery Manufacturing

In the realm of agricultural machinery manufacturing, precision, efficiency, and innovation are indispensable.

Tractor half-shafts, the vital components responsible for transmitting power from the transmission to the wheels, embody the intersection of engineering excellence and agricultural ingenuity.

However, the traditional methods of manufacturing these critical components often fell short in meeting the demands of modern agriculture.

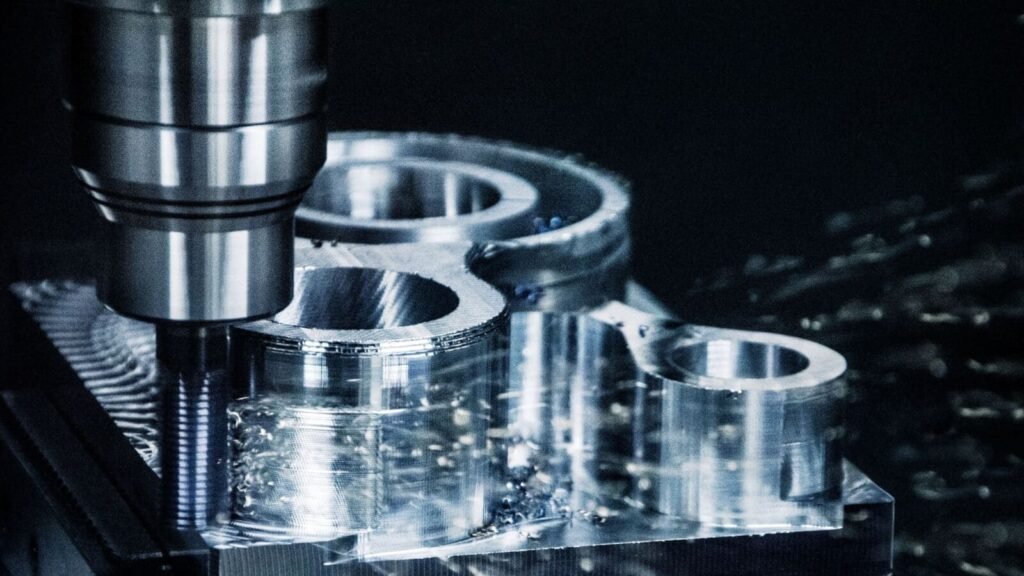

Enter Computer Numerical Control (CNC) machining – a groundbreaking technology that has transformed the landscape of tractor half-shaft production.

In this article, we will explore how advanced CNC machining techniques are unlocking new levels of efficiency, precision, and reliability in tractor half-shaft manufacturing.

Understanding Tractor Half-Shafts: The Backbone of Agricultural Machinery

Tractor half-shafts are the unsung heroes of agricultural machinery, silently transferring power and torque to ensure seamless operation in the field.

These robust components endure high loads, intense vibrations, and harsh environmental conditions, making their reliability and durability non-negotiable. However, traditional manufacturing methods often struggled to meet the stringent requirements of modern agricultural equipment.

Conventional machining processes lacked the precision and consistency needed to produce half-shafts that could withstand the rigors of agricultural use.

As a result, manufacturers faced challenges in maintaining quality standards, optimizing production processes, and meeting market demands.

The Power of Precision: Unleashing CNC Machining Capabilities

The advent of CNC machining revolutionized the manufacturing landscape by offering unprecedented levels of precision, repeatability, and efficiency.

Unlike traditional machining techniques that relied on manual operation, CNC machining harnesses the power of computer-controlled systems to execute intricate manufacturing tasks with unmatched accuracy.

Every cut, every drill, and every turn is meticulously orchestrated by advanced software, ensuring that each half-shaft meets the exacting specifications required for optimal performance.

The precision afforded by CNC machining extends beyond dimensional accuracy; it encompasses every aspect of the manufacturing process, from material selection to surface finish.

With CNC machining, manufacturers can achieve uniformity in half-shaft production, minimizing variations and ensuring consistent quality across every component.

Tight tolerances, smooth surfaces, and precise geometries are the hallmarks of CNC-machined half-shafts, setting new standards for excellence in agricultural machinery manufacturing.

Efficiency Redefined: Streamlining Production Processes

In addition to precision, CNC machining offers unparalleled efficiency, allowing manufacturers to streamline production processes and optimize workflow.

Advanced CAD/CAM software enables engineers to design intricate half-shaft geometries and simulate manufacturing processes with remarkable accuracy.

From prototyping to final production, every stage of the manufacturing journey is optimized for maximum efficiency and productivity.

One of the key advantages of CNC machining is its ability to produce complex geometries and intricate features with ease.

Manufacturers can explore innovative designs and incorporate enhancements that were previously unattainable with conventional machining methods.

By leveraging the flexibility and versatility of CNC machining, businesses can respond swiftly to market demands, customize half-shafts to meet specific requirements, and stay ahead of the competition.

Moreover, CNC machining significantly reduces lead times and production cycles, enabling manufacturers to accelerate time-to-market and capitalize on emerging opportunities in the agricultural machinery sector.

By streamlining production processes and minimizing waste, CNC machining enhances operational efficiency, boosts productivity, and drives sustainable growth in the industry.

Quality Assurance: Ensuring Reliability and Durability

In the competitive landscape of agricultural machinery manufacturing, quality assurance is paramount. Tractor half-shafts must withstand the harshest operating conditions while delivering consistent performance and reliability.

CNC machining plays a pivotal role in upholding quality standards and ensuring the durability and integrity of half-shaft components.

Through advanced machining techniques and precision tooling, manufacturers can achieve superior surface finishes, tighter tolerances, and enhanced material properties.

CNC-machined half-shafts exhibit exceptional strength, resilience, and resistance to wear and tear, prolonging service life and reducing maintenance costs for end-users.

Rigorous quality control measures, including inspection and testing protocols, further reinforce the reliability and performance of CNC-machined half-shafts, instilling confidence in customers and ensuring satisfaction in the field.

Embracing Innovation: Driving Future Advancements in Agricultural Machinery

As technology continues to evolve, the possibilities afforded by CNC machining are virtually limitless. Manufacturers are embracing innovation and exploring new frontiers in tractor half-shaft production, driven by a relentless pursuit of excellence and a commitment to pushing the boundaries of possibility.

From integrating smart sensors and predictive analytics to leveraging advanced materials and composite structures, the future of agricultural machinery manufacturing holds immense promise for innovation and advancement.

Continuous research, development, and collaboration are essential to driving future advancements in agricultural machinery manufacturing.

By harnessing the collective expertise of engineers, designers, and technologists, manufacturers can pioneer new technologies, develop groundbreaking solutions, and redefine the standards of excellence in tractor half-shaft production.

Together, we can shape the future of agriculture, one precision-engineered component at a time.

Conclusion: Pioneering the Future of Agricultural Machinery Manufacturing

In conclusion, advanced CNC machining techniques have revolutionized tractor half-shaft production, unlocking new levels of efficiency, precision, and reliability.

By harnessing the power of computer-controlled systems and embracing innovation, manufacturers can optimize production processes, uphold quality standards, and drive sustainable growth in the agricultural machinery industry.

As we look to the future, let us continue to push the boundaries of possibility, pioneer new technologies, and shape the future of agricultural machinery manufacturing – one precision-engineered component at a time.

Together, we can build a brighter, more sustainable future for agriculture, empowering farmers and driving progress around the world.