Trusted by WORLD CLASS brands

WHO WE ARE

Taizhou AG Tractor Parts Co., Ltd.

Taizhou AG Tractor Parts Co., Ltd. Founded in 2017 in China, nestled in Taizhou, China’s hub for automotive chassis components,specializes in manufacturing top-quality tractor half axles.

With a dedicated team of 70, our 2,000 square meter facility produces over 700 product models, boasting an annual output of $5 million. Catering to North and South America, Brazil, and Europe, we prioritize quality, efficiency, and affordability. Our B2B model focuses on long-term partnerships with procurement officers in large companies. Compliant with international standards like ISO 9001 and IATF 16949, we’re committed to innovation, sustainability, and customer satisfaction.

WHAT WE OFFER

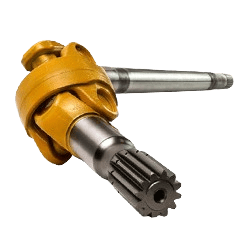

Featured Tractor Front Axle Assembly in the Mraket

We are the production base behind you to take your business to the next level. You’ll get real factory prices with high-quality products. So please tell us what you need, and we’ll take care of the rest.

"AG" will be Your Partner, not Just Supplier.

By choosing us, you’re not just selecting a supplier; you’re embracing a partner dedicated to resolving the specific challenges your business faces. Let’s work together to propel your agricultural operations to new heights of success.

Quality Assurance for Peace of Mind

Warranty: Two years or 10,000 kilometres

why us

What “AG” Can Do to Higher Your Business?

In the realm of agricultural machinery, we understand that your primary concerns revolve around quality, cost, and efficiency. At Taizhou AG, we specialize in turning these challenges into growth opportunities for your business.

Professional and Efficient Team

our team has 12 years of production experience in the industry, bridging the gap between sales understanding and technical knowledge. Our team has the ability to provide you with all the technical insights you need to make your decision-making process smoother and more informed.

Customised Services

Now that the industry has entered a state of full competition, the best solution to make your brand stand out is to “be different and avoid homogeneity”. Tell us the feedback you get from the market, and we’ll take care of implementing them into your products, including customisation of performance, appearance and packaging. Make your brand really stand out.

Cost-Effective Solutions Without Compromise

We understand the balance needed between quality and price. Our competitive pricing model ensures you receive top-quality products without straining your budget, maximizing your profit potential.

Quality Assurance for Peace of Mind

Provides a 2-year or 80,000km warranty.With rigorous testing and compliance with international standards like ISO 9001 and IATF 16949, we guarantee components that enhance the performance and reliability of your machinery.

Navigate Supply Chain Complexities

Our factory is located in Taizhou, the production centre for automotive chassis components in China.With our robust logistics network and timely delivery commitments, we tackle the pain point of delayed shipments. Your orders arrive when you need them, ensuring you never miss your peak sales seasons.

"AG" will be Your Partner, not Just Supplier.

By choosing us, you’re not just selecting a supplier; you’re embracing a partner dedicated to resolving the specific challenges your business faces. Let’s work together to propel your agricultural operations to new heights of success.

Our Advantages

From Roughs to Assemblies Are All Made by Us

Extreme cost control, strict quality control, rich market experience, and good communication are incomparable to any factory.

Why Us?

Not all axle shaft assembly are the same;Let’s talk about our stand-out.

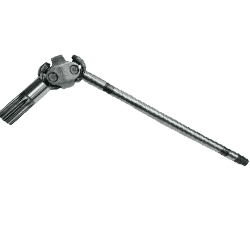

High-Grade 40Cr Steel: The Backbone of Durability

Our tractor half axles are crafted from premium 40Cr steel, a medium carbon alloy steel renowned for its high strength and toughness. This meticulously chosen material, belonging to the Chromium-Molybdenum (Cr-Mo) steel category, includes a strategic blend of about 0.40% carbon, 1.00% chromium, and balanced additions of manganese, silicon, and molybdenum. The result is a product capable of withstanding heavy loads and stresses without significant deformation, ensuring long-lasting performance in demanding agricultural environments.

High-Quality Grease

We use Kyodo Yushi AFI grease, made in Japan and specially designed for wheel bearings; it has a long lifespan and performs well in extreme weather.

Without the grease, the best bearing in the world would fail very quickly. So, it’s essential to use high-quality grease that will last the life of the bearing.

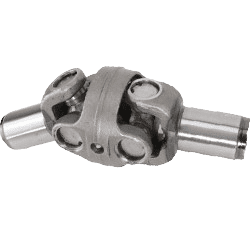

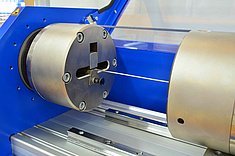

Universal Joint Clearance

The universal joint is an important component of the axle shaft, so the clearance of the universal joint is also an important performance that affects driving. The national standard of universal joint clearance is 0.03-0.05mm, and our universal joint clearance is generally lower than 0.03mm.

PRODUCTION PROCESS

Production Process

See our production process to let you know how your product is made.

Forging

Forging:

Machining

Machining

Heat Treatment

Heat Treatment

Assembly

Assembly

Surface Treatment

Surface Treatment

Packaging and Logistics

Packaging and Logistics

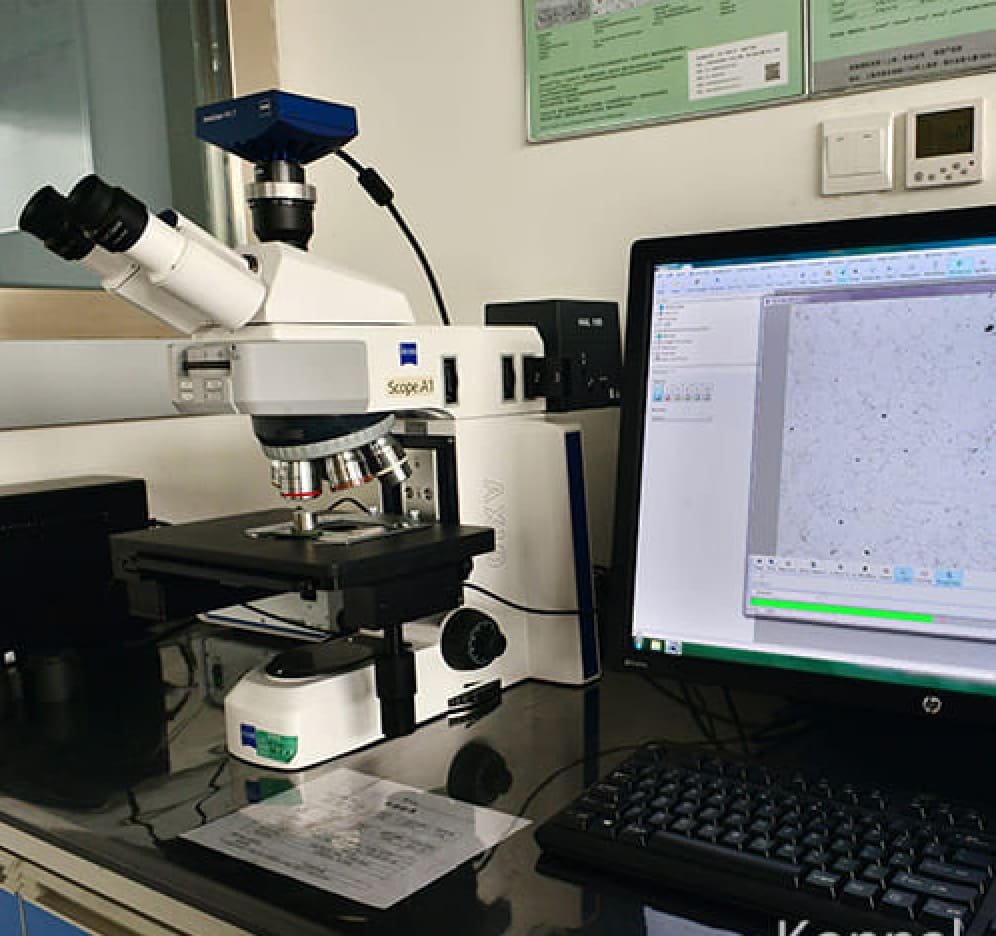

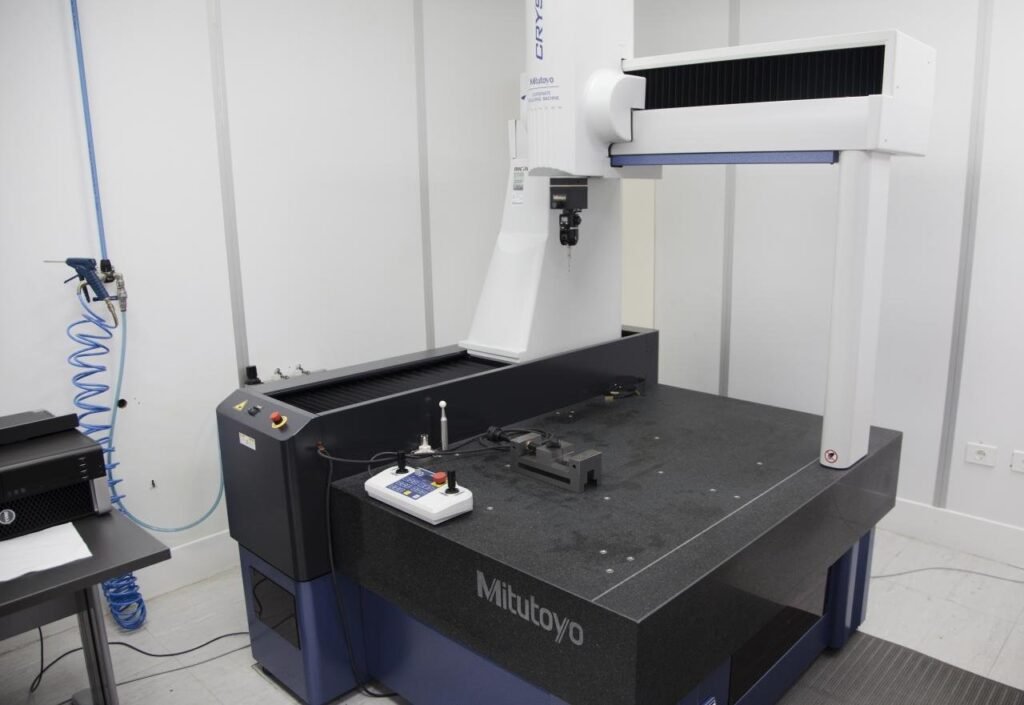

Quality control

Quality Control Flow

From rough to finished products, we ensure that each step will be thoroughly inspected to prevent unqualified products from flowing into the following process.

1. Roughs:

Pick out defective substandard roughs.

2. Machining:

Pick out the out-of-tolerance parts.

3. Assembly:

Pick out products with universal joints clearance.

4. Surface treatment:

Pick out the products with uneven and unattractive surface treatment.

5. Final inspection:

First, check whether the product expansion size and installation size meet the requirements of the drawings. Secondly, check whether the appearance of the product has any defects. Finally check the packaging details, such as check whether the product laser marking, packaging, labeling and markings meet customer requirements.

Get Started With AG Now!

The perfect solution will make your brand stand out in the market; tell us what you need now!

Durable packaging

Whatever your packaging requirements, please let us know, and we’ll take care of it for you!

Neutral Packing

Customised laser, neutral bags, neutral boxes

International standard fumigation-free pallets

Brand Packing

Customised lasers, labels, branded bags, branded boxes

International standard fumigation-free pallets

Step into our production plant

Let's Be Great Together

Unlock Your Competitive Edge: Inquire Now for Unmatched Tractor parts Solutions!

We have been doing only one thing for the past 7 years. This is to “make good front axle assembly”; we will continue to do this in the future.

TESTIMONIAL

What Our Lovely Customers Say

We have served hundreds of satisfied customers; many of them have established deep friendships; they are from the USA, Canada, Mexico, Brazil, Argentina, Peru, Australia, New Zealand, Germany, France, the UK, Italy, Netherlands, Poland, Russia, Ukraine, Spain, Hungary, Turkey, Saudi Arabia, Malaysia, Thailand, etc. Here are some reviews they left for us.

Maple AgriTech Solutions, Inc.

Senior Procurement Manager

“I’ve been dealing with Taizhou AG Tractor Parts for a while now, eh. What stands out is their straightforward approach. Their parts? Top-notch and fairly priced. Bella and her team, they’re real pros – no sugarcoating, no nonsense. They get how things work here in Canada, and that’s a big deal. So, if you’re up north and need dependable tractor parts, Bella’s team is the way to go, hands down.”

Verde Agricultura e Maquinário Ltda.

Chief Supply Chain Officer

“Olha, trabalhar com AG Tractor Parts tem sido uma boa jogada. Estamos juntos há uns três anos e os eixos de trator deles são de primeira linha. O que me pega mesmo é o preço. Pra gente aqui, isso conta muito, e eles têm um preço justo. Tivemos alguns atrasos quando começamos a trabalhar juntos, mas eles os resolveram rapidamente!Se você tá no Brasil e procura por peças de qualidade sem dor de cabeça, fala com a Bella.”

Agricultural Technical Solutions Sp. z o.o.

Director of Purchasing

continuously impressed by their dedication to quality and efficiency. Their tractor parts are not only top-tier in quality but also competitively priced. Their adherence to quality standards and timely deliveries has been pivotal in helping us meet our sales targets, especially during peak seasons. I highly recommend AG Tractor Parts for any company looking for reliability and excellence in tractor parts supply.”

Our Certificate

IATF 16949:2016

Please see our IATF 16949:2016 certificate, which is another reflection of our strength; after all, not all axle ftont shaft factories have the ability to obtain this certificate.

COMMON QUESTIONS

Frequently Asked Questions

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity is 100 pcs, because some models we have in stock, and for those we don’t have in stock, the minimum order quantity is 400 pcs.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms. All subject to customer requirements.

Accurate factory price, no middle man.

Yes, we offer free samples for your test.

All products from Wana Auto Parts are covered with a 24 Months warranty from the date of installation or 10,000 km, whichever comes earlier.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

Usually, for the models we have, the lead time will be less than 45 days; for newly developed products, the lead time will be 60 days.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, anything you need.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

contact us

Get Our Latest Catalog Today!

Want to know more about our latest catalog? Please fill out the form on the right to send us an inquiry. We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!