The agricultural machinery industry is witnessing a significant transformation, fueled by relentless innovation and the adoption of cutting-edge technology.

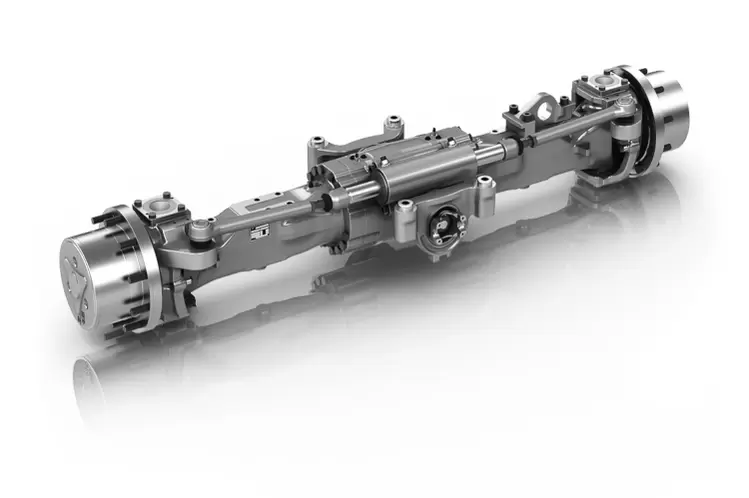

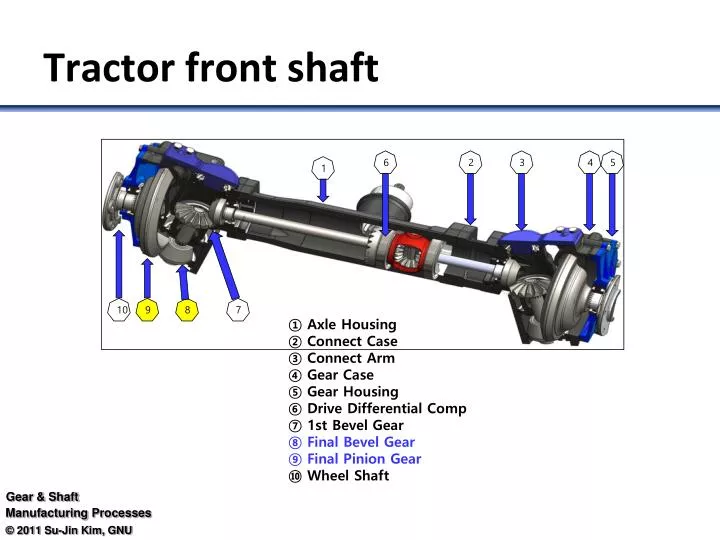

At the heart of this revolution lies the tractor front axle shaft, a critical component that significantly impacts the efficiency, reliability, and overall performance of tractors.

This article delves into the latest advancements in tractor front axle shaft design, offering insights into how these innovations are setting new benchmarks in the industry.

Q1: How have materials used in front axle shafts evolved to enhance durability and performance?

A: The industry has seen a shift towards using high-grade materials such as advanced steel alloys and composite materials for front axle shafts.

These materials offer superior strength-to-weight ratios, exceptional durability, and resistance to wear and corrosion.

The adoption of such materials not only extends the lifespan of the shafts but also improves their ability to withstand the harsh conditions often encountered in agricultural settings, ensuring that your machinery operates at peak efficiency for longer periods.

Q2: What role does computer-aided design (CAD) play in the innovation of front axle shafts?

A: CAD has revolutionized the design process of front axle shafts by allowing for more precise and efficient engineering solutions.

This technology enables designers to create complex geometries that optimize the distribution of stress across the shaft, enhancing its strength and durability.

CAD also facilitates rapid prototyping, allowing for quicker iterations and testing, which accelerates the development of innovative solutions tailored to meet the specific needs of modern agricultural practices.

Q3: Can you elaborate on the significance of weight reduction in the latest front axle shaft designs?

A: Weight reduction plays a pivotal role in enhancing the fuel efficiency and maneuverability of tractors. By incorporating lighter materials and optimizing shaft designs, manufacturers are able to reduce the overall weight of the tractor without compromising the structural integrity or performance of the axle.

This not only results in lower fuel consumption but also minimizes soil compaction, preserving soil health and productivity.

Q4: How are advancements in manufacturing processes contributing to the quality of front axle shafts?

A: Cutting-edge manufacturing techniques such as precision forging, laser welding, and additive manufacturing (3D printing) have greatly improved the quality and consistency of front axle shafts. These processes allow for tighter tolerances, improved material properties, and the integration of complex features that were previously difficult or impossible to achieve.

As a result, today’s front axle shafts are more reliable and better suited to the demands of advanced agricultural machinery.

Q5: What innovations in sealing and lubrication technologies are being introduced to improve the longevity of front axle shafts?

A: To combat the ingress of dirt, water, and other contaminants, manufacturers are implementing advanced sealing technologies that offer enhanced protection against harsh environmental conditions.

Simultaneously, innovations in lubrication systems, such as the use of long-life synthetic lubricants and automated lubrication delivery systems, ensure that front axle shafts maintain optimal performance throughout their service life.

These advancements significantly reduce maintenance requirements and downtime, boosting overall operational efficiency.

Q6: How does integration with smart technology contribute to the functionality of front axle shafts?

A: Smart technology integration allows for real-time monitoring of front axle shaft conditions, including wear, temperature, and load distribution.

This data can be used to predict maintenance needs, prevent failures, and optimize performance based on varying operational conditions.

Additionally, the incorporation of smart sensors and IoT (Internet of Things) connectivity enables remote diagnostics and adjustments, further enhancing the tractor’s efficiency and reliability.

Q7: In what ways are environmental considerations influencing the design of front axle shafts?

A: Environmental sustainability is increasingly becoming a priority in the design of front axle shafts.

Manufacturers are exploring eco-friendly materials and manufacturing processes that reduce carbon footprints, such as the use of recycled materials and energy-efficient production methods.

Moreover, the shift towards lighter, more efficient shaft designs contributes to lower fuel consumption and emissions, aligning with global efforts to combat climate change.

Q8: What future trends do you foresee in the design and manufacturing of tractor front axle shafts?

A: The future of tractor front axle shaft design is poised for further innovation, with a focus on integrating advanced materials science, nanotechnology, and artificial intelligence to create even lighter, stronger, and more intelligent components.

The application of AI in predictive maintenance and performance optimization, along with the continued push towards sustainability, will shape the next generation of tractor front axle shafts, ensuring that they meet the evolving demands of the agricultural industry.

Conclusion

The agricultural machinery sector is at the cusp of a technological revolution, with the tractor front axle shaft at the forefront of this change.

The latest advancements in materials, design, manufacturing, and smart technology integration are driving unprecedented improvements in efficiency, reliability, and environmental sustainability.

As these innovations continue to evolve, they promise to redefine the standards of performance in the industry, ensuring that agricultural professionals are equipped with the tools they need to meet the challenges of tomorrow.

By staying informed about these developments, procurement officers and agricultural machinery companies can make strategic decisions that leverage the latest technological advancements, ensuring a competitive edge in the market. AG Tractor Parts Co., Ltd. remains committed to leading this charge, offering top-quality, innovative solutions that meet the ever-changing needs of our clients.